Introduction

In the rapidly evolving landscape of industrial automation, remote monitoring control cables play a crucial role in enhancing efficiency, safety, and productivity across various sectors. These cables enable seamless communication between control systems and remote monitoring devices, allowing operators to remotely monitor and control critical processes with precision and accuracy. EMI shielding control cables into the intricate world of remote monitoring control cables, exploring their significance, applications, technologies, and future prospects.

Significance of Remote Monitoring Control Cables

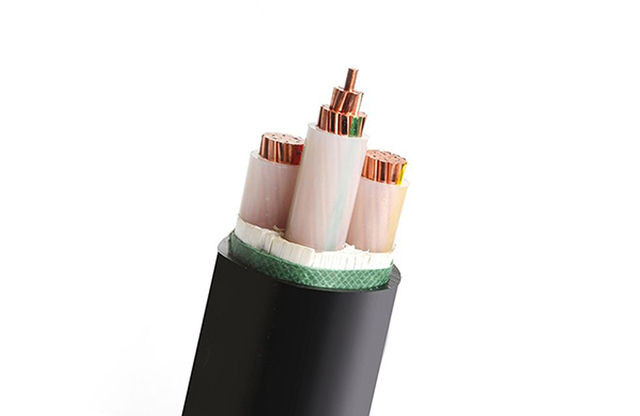

Remote monitoring control cables serve as the lifeline of modern industrial operations, enabling real-time data transmission and control functions across vast distances. These cables are designed to withstand harsh environmental conditions, electromagnetic interference, and mechanical stress, ensuring reliable and uninterrupted communication between control systems and remote monitoring devices. By utilizing advanced technologies such as fiber optics, wireless communication, and secure protocols, remote monitoring control cables offer a high level of data integrity, security, and scalability, making them indispensable in critical industries such as oil and gas, utilities, manufacturing, and transportation.

Applications of Remote Monitoring Control Cables

The applications of remote monitoring control cables are diverse and encompass a wide range of industries and sectors. In the oil and gas industry, these cables are utilized for remote monitoring and control of drilling operations, pipeline infrastructure, and offshore platforms, enabling operators to optimize production, enhance safety, and minimize downtime. In the utilities sector, remote monitoring control cables play a vital role in managing power grids, water treatment facilities, and renewable energy installations, facilitating efficient operation, fault detection, and maintenance scheduling. In manufacturing plants, these cables enable remote monitoring of production lines, robotic systems, and quality control processes, improving operational efficiency, product quality, and overall productivity.

Technologies Used in Remote Monitoring Control Cables

Remote monitoring control cables leverage a variety of technologies to ensure reliable and secure data transmission between control systems and remote monitoring devices. Fiber optic cables are widely used for long-distance communication due to their high bandwidth, low latency, and immunity to electromagnetic interference. Wireless communication technologies such as Wi-Fi, Bluetooth, and cellular networks provide flexibility and mobility in remote monitoring applications, allowing operators to access real-time data from anywhere within the network coverage area. Secure protocols such as VPNs (Virtual Private Networks) and encryption algorithms are employed to protect sensitive data transmitted over remote monitoring control cables, ensuring confidentiality and integrity of information.

Future Prospects of Remote Monitoring Control Cables

The future of remote monitoring control cables is poised for significant growth and innovation, driven by advancements in automation, artificial intelligence, and Internet of Things (IoT) technologies. As industries embrace digital transformation and Industry 4.0 initiatives, the demand for intelligent remote monitoring solutions will continue to rise, creating new opportunities for remote monitoring control cable manufacturers and service providers. Integration of machine learning algorithms, predictive analytics, and autonomous control systems will revolutionize the way remote monitoring control cables are utilized, enabling proactive maintenance, predictive diagnostics, and real-time decision-making in industrial operations.

Conclusion

Remote monitoring control cables are the backbone of modern industrial automation, enabling seamless communication and control of critical processes across vast distances. With their robust design, advanced technologies, and diverse applications, these cables play a pivotal role in enhancing efficiency, safety, and productivity in industries ranging from oil and gas to utilities and manufacturing. As the digital transformation continues to unfold, the future of remote monitoring control cables holds immense promise, with innovations in automation, AI, and IoT set to redefine the capabilities and possibilities of remote monitoring systems. By leveraging the power of remote monitoring control cables, industries can unlock new levels of operational excellence, cost savings, and competitive advantage in the dynamic landscape of industrial automation.